Cleaning Machines

Cleaning machines

The available hardware and its capability/restrictions must be considered carefully. The most important tool during tank cleaning operation is obviously the tank cleaning machine(s).

A crucial design criterion of the tank cleaning machine is the number of nozzles

Most types are Single Nozzle or Dual Nozzle.

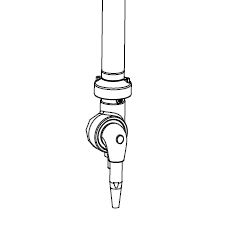

Single nozzle machine

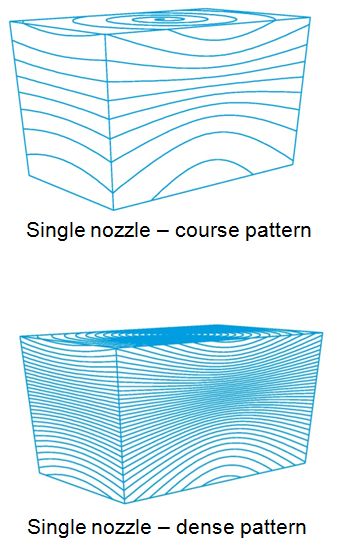

Single nozzle machines require setting/programming before the cleaning commences. Usually, these machines have 4 different programs, based on the pitch angle, which is the angle the nozzle deviates from 0o with each full rotation. Typically program 1 generates the densest pattern and program 4 the coarsest pattern.

At the start of cleaning, the nozzle is at 0o and points directly upwards, firing the jet of water at the underside of the deck head. The nozzle then spins and rotates and after one complete rotation, the pitch is increased according to the programming. Thereafter, the nozzle spins and rotates again and this process is repeated until the nozzle ends up 180o from the starting position, pointing down to the tank top, which represents the end of one full cleaning cycle. The smaller the change in pitch, the more intense the cleaning becomes because it takes longer to move the nozzle from 0o around to 180o. If the machine is not stopped manually at the end of the cycle, it will continue to move from 180o back up to 0o at the same preset pitch angle.

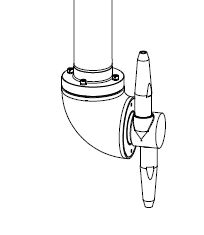

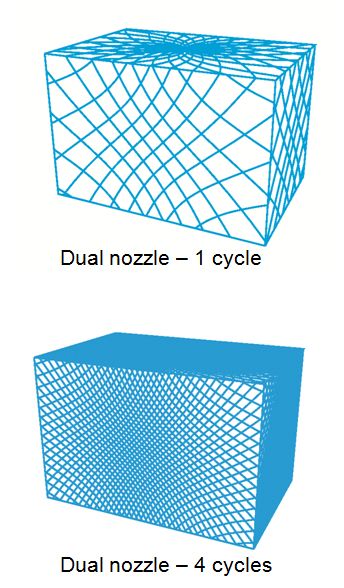

Dual nozzle machine

Dual nozzle machines do not need to be programmed. Due to the dual nozzle arrangement, a typical criss-cross pattern is produced during the cleaning, which very often can be observed on the tank walls, if the previous cargo is coloured or particularly viscous. Dual nozzle machines achieve full coverage of the tank in a much shorter time frame compared to single nozzle machines. With increased cleaning time the cleaning coverage / pattern becomes denser and denser. Generally, after 4 cycles full coverage of the tank is achieved.